Manufacturing Capabilities

Proscend has well-developed production abilities and well-organized manufacturing implementation capabilities for growing together with our customers and production partners. Our manufacturing production partners have received ISO 9001 certification and listed on UL qualification. With long-term trusted cooperative relationship, our enterprise spirit is not just to satisfy our customers, but strive to exceed customer expectations.

With disciplined quality management system from production, testing, assembling, and product inspections, our manufacturing production partners are well-positioned in excellent in-house facilities and production-planning expertise to effectively control quality procedures and delivery time for our high-quality products, including Industrial Cellular Routers, Long Reach Power Over Ethernet Extenders, DSL SFP Modems, and SHDSL Routers, etc.

Proscend is able to providing perfect customized services based on our solid technological strength and high-quality control capability. We are highly concerned about customer demands to create your unique value and fulfill requirements to achieve stronger profit margins and firmer growth in your global marketplace.

The Brief of Manufacturing Capabilities in Taiwan:

✓ SMT Process

● Three fully automatic high-speed SMT production lines that can produce a daily maximum of 3,000,000 point components.

● PCB SIZE (MAX.): 300 mm x 400 mm

✓ DIP Process

● Two insertion, touch-up, and hand soldering lines and non-lead furnace DIP production lines

● 1 Burning Room

✓ TEST & ASSEMBLY

● Test Line: Up to 60 Stations to deliver strict quality checks

● 1 Assembly Line & 1 Packing Line

● Overall ERR Rate < 0.1%

- Skilled operators assemble products at the assembly line.

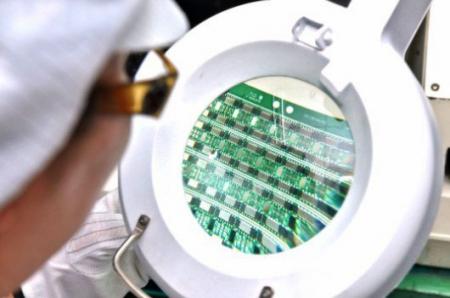

- Skilled workers check components carefully.

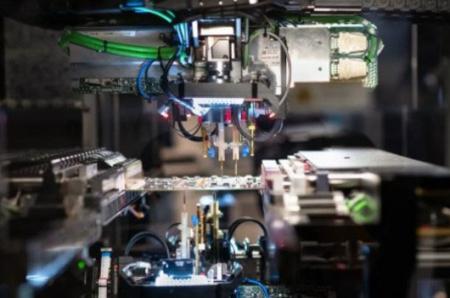

- Skilled staff use professional machine to check components.

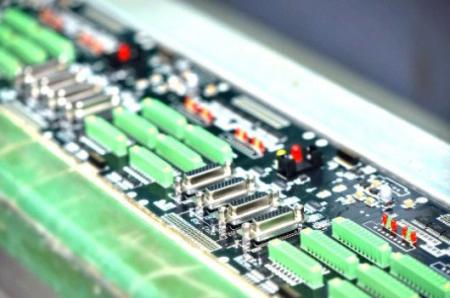

- The components is on the assembly line.

- Using professional machine to assemble products.

- Operating precision equipment to manufacture products.

- The precision machine is operated to assemble products.